FAQS - All you need to know when choosing your Wood Flooring

What types of wood floors do FLOORING

FLOORING

What is Engineered Wood Flooring?

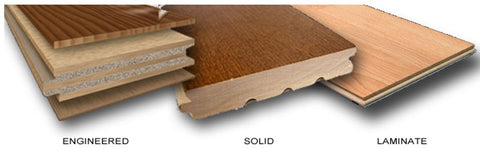

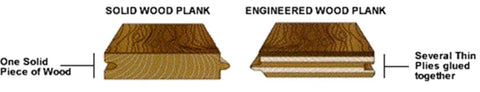

An engineered board is a timber board which consists of more than one layer. By placing each layer so that the grain runs perpendicularly it becomes virtually impossible for the timber to swell or shrink with changes in humidity and so it dramatically increases the stability. The top layer of an engineered board (the lamella) is solid wood, usually hardwood, and may be anything from 2 to 6mm thick; obviously the thicker the surface layer the more times it can be sanded and refinished to remove the ravages of wear; the thickest wear layers are equivalent to those on solid timber boards. The lamella is securely bonded to one or two further layers – this may be a multi-layered plywood or a sandwich with either a softwood or hardwood core.

Engineered boards should not be confused with laminate or veneer. Laminate uses an image of wood on its surface whilst veneer uses only a very thin layer of wood over a core of some type of composite wood product, usually fibreboard.

Engineered timber is now the most common type of wood flooring used globally and the technology has enabled the production of much wider boards as well as the application of an enormous variety of really interesting finishes.

What is Laminate Flooring?

Laminate flooring is constructed in layers. The bottom layer is the "backing". It's designed to resist moisture that could cause boards to warp.

Above the backing is the inner core. The core is made from high-density fiberboard that is reinforced with a special resin to further enhance moisture resistance and increase durability.

Next is the image design layer. This is where the high-resolution image of wood, stone, metal, or other material appears. If you've selected a laminate floor with MasterWorks Technology® with VTX™, this is where the texture is applied to enhance its realistic appeal.

The top layer is the wear layer. This layer protects the design from fading, scratches, and damage from everyday wear and tear.

What is Solid Wood Flooring?

A solid wood floor is floor laid with planks or boards which have been milled from a single piece of timber, usually a hardwood. Since wood is hydroscopic (it acquires and loses moisture from the ambient conditions around it) this potential instability effectively limits the length and width of the boards. Solid hardwood flooring is usually cheaper than engineered timbers and damaged areas can be sanded down and refinished repeatedly, the number of timbers being limited only by the thickness of wood above the tongue. Solid construction timber is often used for sports floors and most traditional wood blocks, mosaics and parquetry are also of solid construction.

What do the grades mean when buying wood flooring?

The wood used by manufacturers will be given grades according to the appearance. In general, the features taken into account when grading wood include the number and size of knots; the amount of sap in the wood and its colour variations. Generally, the smaller the knots, the lower the sap content and the more uniform the colour, the higher the grade of wood and the more expensive the wood floor will be.

When it comes to choosing which wood grade is best for your wooden flooring, there are four grades of wood to choose. Each grade gives a slightly different look.

The grades are:

- Prime or AB

- Select or ABC

- Natural or ABCD

- Rustic or CD

In order to help you choose your wood grading for your hardwood flooring here are some of the characteristics of each grade:

Prime Grade

This is the highest grade of wood flooring. Prime grade can also be known as AB-high grade. This will be cut from the centre of the log; its grade of wood is consistent in its appearance and will have limited knots. If the quality of wood grade does contain knots, they will be small and discreet. In addition, the sap content of the wood is very low. Finally, and often one of the most important considerations when it comes to choosing a wood grade, the colour variation is minimal, due to the fact that wood is a natural product. A Prime grade floor will have a more consistent look.

Select Grade

Select Grade is the next grade of wood flooring. Often labelled as ABC grade, this wood contains some knots, but less than Natural grade, some sap and some colour disparity.

Natural Grade

Natural grade is next grade of wood. Also known as ABCD grade, This is the most common grade and contains bigger knots than select grade and will contain more sap and has even more colour variation. This can be the most cost effective grade depending on your needs.

Rustic Grade

Rustic Grade is the last grade of wood flooring. It will display a larger variety of colour, sap and will have more knots and fillers, this will be the least expensive but the advantages will be it gives your floor a good-looking, traditional vintage look.

What is Acclimatizing? (Acclimatise)

Acclimatizing (or acclimating) flooring means allowing it to adjust to the temperature and humidity of the room where it will be installed. This helps prevent expansion, contraction, warping, or buckling after installation.

-

Solid hardwood: 5–7 days (sometimes longer)

-

Engineered wood: 2–3 days

-

Laminate/Vinyl: 24–72 hours

Always check the manufacturer's guidelines.

What installation method shall I use for my wood floor?

There are varieties of installation methods you can use to install your floor. It depends on what type of floor you have bought and method of fitting you would prefer. Here is a guide to the different installation methods you can use for Solid Wood, Engineered and Laminate wood floors.

Solid Wood Flooring

For a solid wood floor, either you can glue it to the sub floor using a polymer adhesive or depending on the sub floor; you could secret nail it down.

Engineered Wood Flooring

For an engineered wood floor you can either secret nail, glue or float it depending on the type of sub floor.

Laminate Wood Flooring

For a laminate wood floor, the only installation method available is to float your floor onto your sub floor.

What is a floated floor?

A floating floor is a floor that does not need to be nailed or glued to the subfloor.

First of all we you should cover the subfloor with a foam pad and staple the pad in place with a hammer tacker. Next set first plank in place with the tongue edge facing the wall or baseboard moulding. Now tap together the planks in the first row, end to end. Be sure to use a tapping block to prevent damaging the flooring. Install the planks in the second row, making sure you stagger the end joints from the previous row. Hold the planks at a slight angle and tap them into the first-row planks with a dead-blow hammer. Insert spacer blocks between the flooring and wall or baseboard to create an expansion space. Use a jamb saw to trim door casing so the flooring will slip underneath. Set plank in front of doorway and use scribing tool to transfer cut lines from the doorway to the plank. Cut the plank to size with a jigsaw. Tap the plank into the doorway, making sure it slips under the casings. Continue installing planks across the room. When necessary, use a pull bar to tap the joints tight between the planks.

Once all the flooring is installed, remove the spacer blocks and nail shoe moulding around the room perimeter. Be sure to nail the shoe to the baseboard, not the floor.

What is a secret nailed floor?

With the introduction of tongue and grooved oak boards, the secret nailing method is the most commonly used method for floor fitting.

This particular method involves driving a fixing through the tongue of each board into the subfloor or joist below. As the tongues are hidden by the groove of the next board, this means the fixings are also hidden. This produces a fixing free finish, hence the name "secret".

It is worth noting that with wider solid oak flooring boards and when using this method, additional surface fixing may be required.

We would always recommend using a moisture barrier paper under the solid or engineered wood floor as this stops any moisture coming through the boards.

Always check the length of the nails before secret nailing the floor to make sure the nail goes straight through the joists and hit any pipes or cables.

How to glue down a floor?

Before you start to glue down your floor make sure the floor is clean and dust free with no loose particles. We would recommend you use a floor prima that is compatible with the adhesive you are going to use.

To start with, you should do four rows at a time making sure all the header joints are sufficiently spaced apart with a minimum of 12 inches. Once you have done four rows, stack the rows on top of each other so the top row of the pile will be the first row of flooring you will glue down. Now chalk a line on the floor, which is parallel with the first row in multiples of four rows. So for example if the boards are 100mm wide and you have to do four rows, chalk a line from the first row 400mm at one end and chalk a line 400mm from the other end and just glue to the chalk line. Therefore, you do not end up with glue going past the fourth row because then the glue may dry and cause a skin, which the floor will not stick to.

The first row you do use a fast set adhesive or brace it off the wall sufficiently enough with wedges or flooring clamps, so the first row is straight and the header joints are nice and even. Once you have done this, you can start your gluing.

We would always advise you use an MS Polymer flexible flooring adhesive, which allows the floor to move with the temperature and adapt to the relative humidity of the different seasons of the year.

What floor can I use if I have underfloor heating?

Laminate flooring is suitable for use with underfloor heating and offers a more robust floor finish. Laminate floors are subject to a 27 degree maximum floor temperature and as with carpet flooring, this means a certain maximum heat output which needs to be taken into account when choosing a system.

Solid Wood flooring is suitable for use with underfloor heating, but as different types of wood have different thermal mass and conductivity, attention should be considered to the thickness and density of the material. The change in floor temperature can also affect some wood flooring so you should always check the suitability of chosen underfloor heating with your wood flooring.

Engineered timber is thought to be the best wood flooring for use with underfloor heating as it does not change appearance when used with the underfloor heating. As with carpet, laminate and vinyl, wood floor temperature must not exceed 27°C. This means that there will be a maximum heat output that is possible to achieve with underfloor heating for wood floors.

How do I maintain my wood floor after I have fitted?

Once you have fitted your floor, it is essential you look after it. To maintain your floor we would recommend the following:

Apply Floor Protector Pads: All moveable furniture need soft clean pads on the bottowm of the legs or support.

Use Door Mats: Keep dirt outside by using door mats placed at all exterior doors

No High Heels: High Heels concentrate a persons weight onto a small point. This kind of force can dent and pit wood floors, fracture ceramic tiles and perforate laminate.

Pets are OK: Dog and Cats owners claws can scratch a wood floor. It is a good idea to trim them regularly. Some finishes like urethanes and Swedish-type finishes are essentially water proof. These are great finishes for pets' households because pet urine will not hurt these floors if cleaned up immediately. Spills from water/food bowls are usally no problem if wiped up staright away.

Use Area Rugs: Some areas of the house experience more wear than others. Kitchens (especially in front of the sink) always have a lot of traffic. Rugs can be used to protect high-traffic areas. Make sure they are kept dry and clean. Shake them well and vacuum frequently.

Moving Heavy Furniture: Remember to pick up heavy furniture and do not slide across the floor. Its a good idea to rent and "Air Sled" or furniture dolly with rubber wheels. Floor guards enable you to move appliances for servicing without damaging your floor.

Cleaning your Floor: Always sweep your floor with a soft brush; never mop your floor with a wet mop. We would strongly recommend buying a maintenance pack or use a Bona spray mop.

Scratches: The most important thing to do about scratches is to find out what caused them. Find the cause and remedy the problem to prevent further scratches appearing. Scuffing or high traffic areas mean gritty shoes or dirty floors, a rug maybe needed for these areas. Lightly scratched areas which have not worn through the raw wood can be lightly buffed. This will shine the area and match the sheen of the rest of the floor, making the scratches less obvious.

How much does FLOORING

FLOORING

We also offer free samples on all products so you can get to see your wood flooring before committing to buy.

Once you have purchased your floor we endeavour to deliver it to you as quickly as possible but please allow up to 3 - 5 working days depending on availability. Our expert customer service team are available during working hours Monday - Friday and will be happy to assist if you have any problems or queries regards your order.

Does my FLOORING